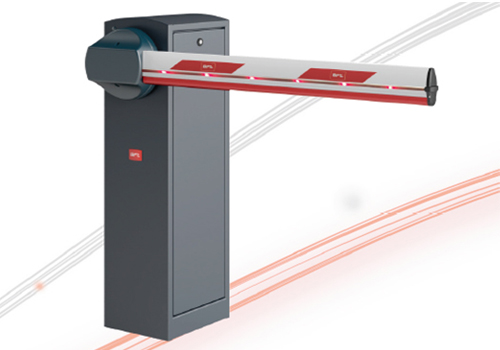

Electromechanical Barriers

General Description

Electromechanical barriers are designed for the controlled flow of traffic, especially for

Cabinet

Barrier cabinet is designed to IP 55. Body font lid and top lid is manufactured from A1 Quality Steel. They are phosphate plated, painted to RAL 2004 and then furnaced. Anchoring to the floor is achieved by a galvanized anchoring plate. There are air circulation openings on the front lid which is opened by a key.

Control Cabinet

barriers are controlled with the help of advanced microelectronics. Barrier works with 220-240V, 50-60 Hz. Every kind of radio control receiver cards, safety photocells, open/close buttons, loop detectors, flashing lights etc. can be integrated

Motor & Reducer

A high torque AC motor is utilized in the barrier. Coupled to the motor, there is a reducer with 1/62 reduction ratio.

ARM

All the elements of the mechanism are manufactured on CNC machines. A 10 mm

Optional Accessories

- Flashing lamp (flashes while the arm is in motion)

- Barrier skirt (aluminum)

- Protection bar (2″ tubing, galvanized, RAL 2004 painted, furnaced)

- Safety photocell

- Stand and casing for safety photocell against direct sunlight, rain, snow,

- Loop detector

- Radio receiver card

- Transmitter

- Antenna

- Stop sign in the middle of

aluminum barrier arm - LED light under the aluminum barrier arm